OUR SERVICES

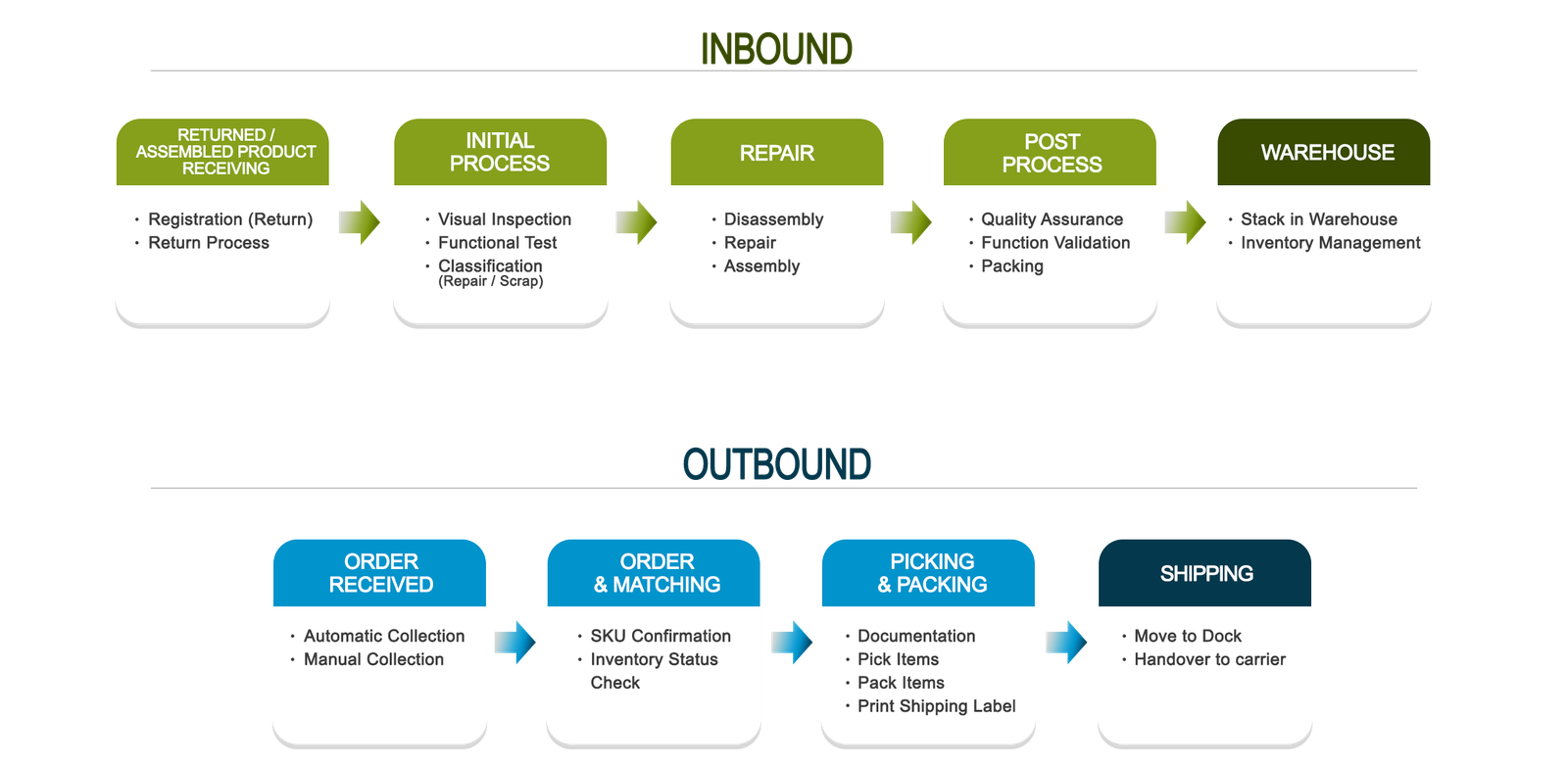

FULFILLMENT / REVERSE LOGISTICS

AQS offers standard fulfillment services in conjunction with our ability to accept returns for reverse logistics purposes, facilitating the refurbishment of products to optimize their lifecycle for resale.

Repair / Refurbishment / Scrap

AQS’s engineers and operators work to perform repairs, offering a range of customizable services tailored to meet our customers' specific needs. Moreover, we dispose materials and unusable goods, relieving our customers the inconvenience and hassle.

Different Types of

Repair Services:

Parts replacement

Disassembly/Reassembly

Parts Installation

Scope of work

for Refurbishment:

for Refurbishment:

Cosmetic Inspection

Grading

Sorting

Cleaning / Sanitize

Shelf/Inventory Return

Repackaging

Material Scrap:

(Certificate of Destruction)

(Certificate of Destruction)

Plastics

Cloth Materials

Metal & Steel

Electronic Components

Glass

Wood

Testing / Firmware Updates

All testing requirements for electronics prior to shipping or upon return can be efficiently managed at our RMA Fulfillment Center. We are committed to upholding high-quality standards to ensure that your customers receive exceptional products and have a positive experience. Additionally, we offer firmware updates to enhance the efficiency and functionality of your product.

Different Types of

Testing Services

Testing Services

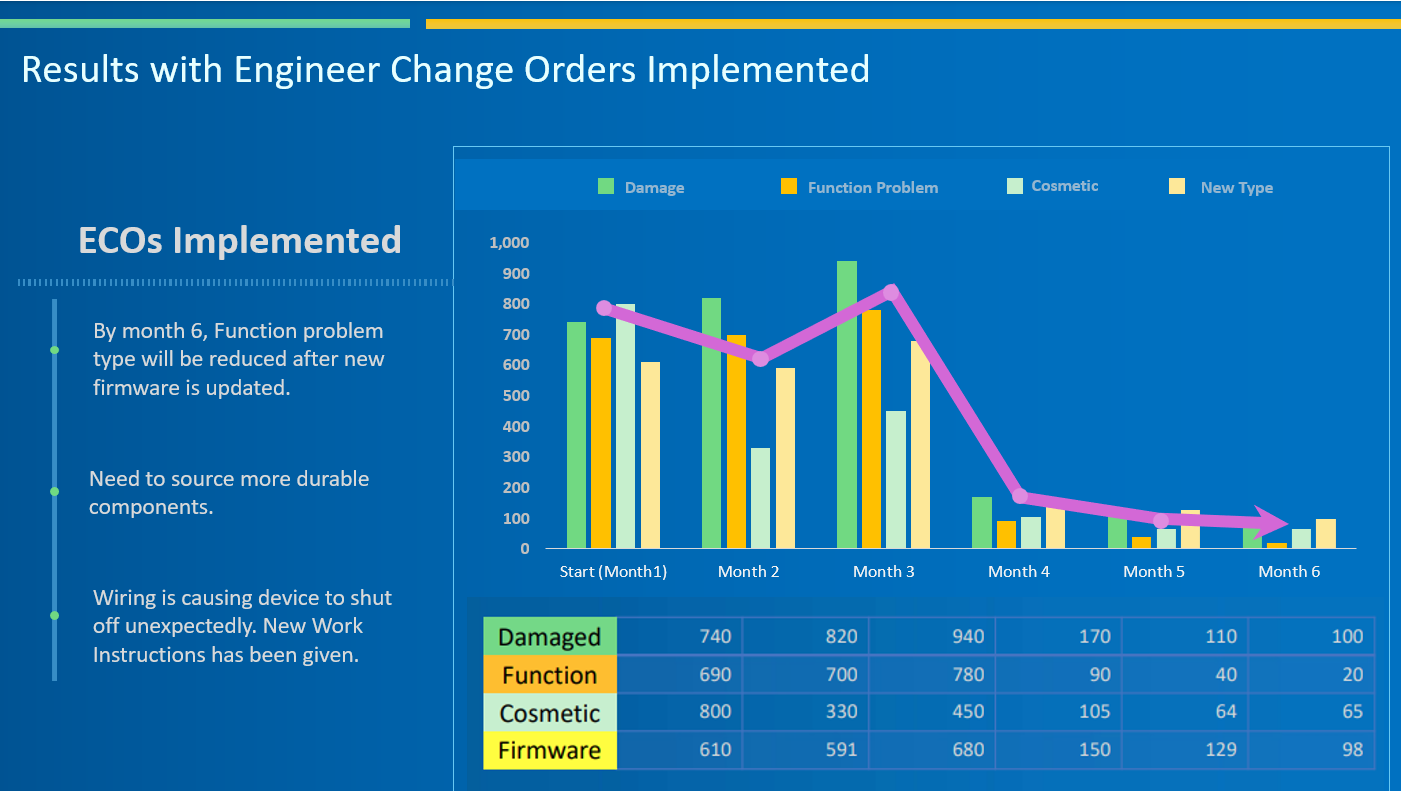

RMA Reduction Services

AQS is committed to collaborative efforts in providing innovative ideas, expert advice, and utilizing our RMA data to identify solutions and implement Engineer Change Orders (ECOs). Our aim is to minimize returns stemming from defects or malfunctions in electronic devices, ensuring enhanced product quality and customer satisfaction.

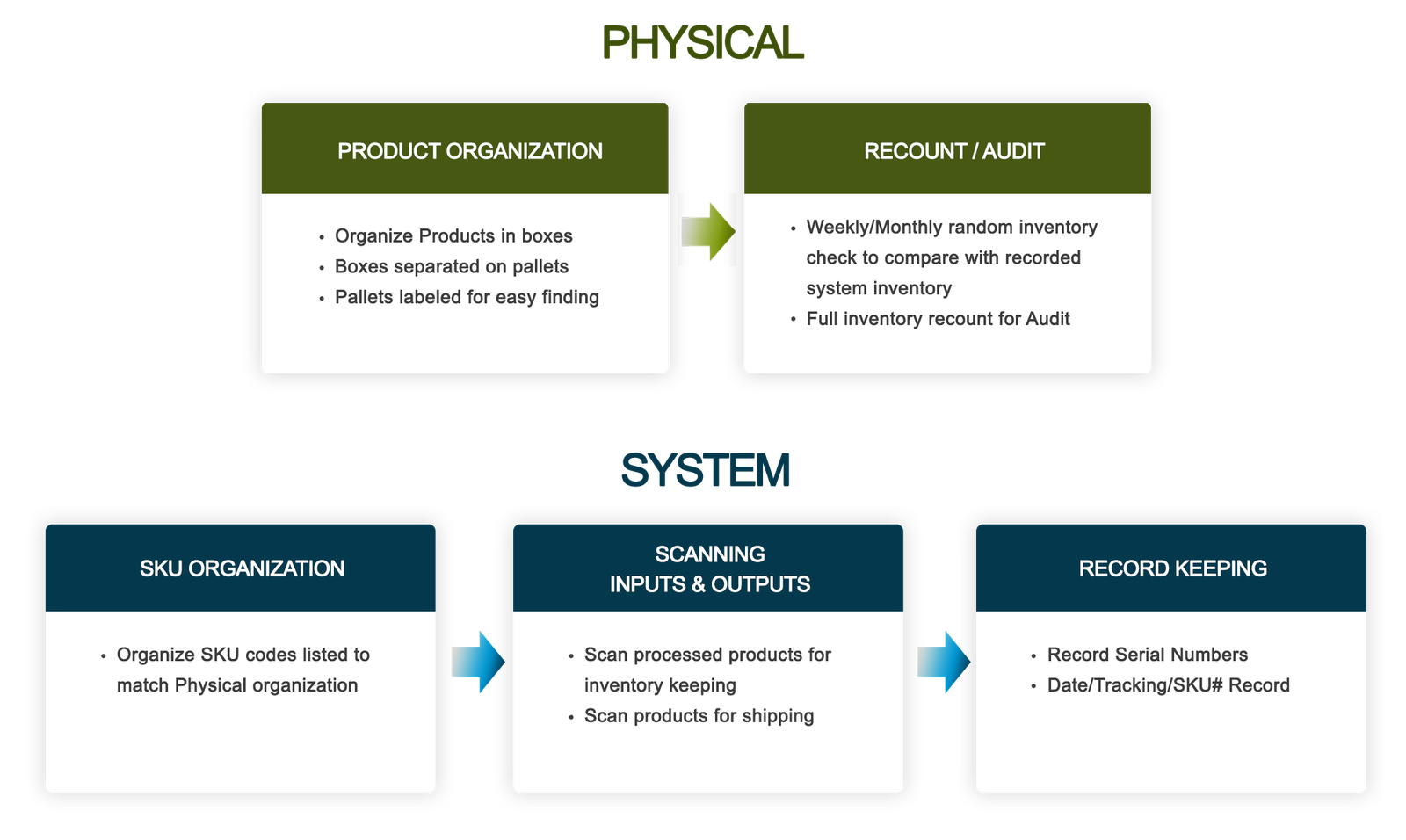

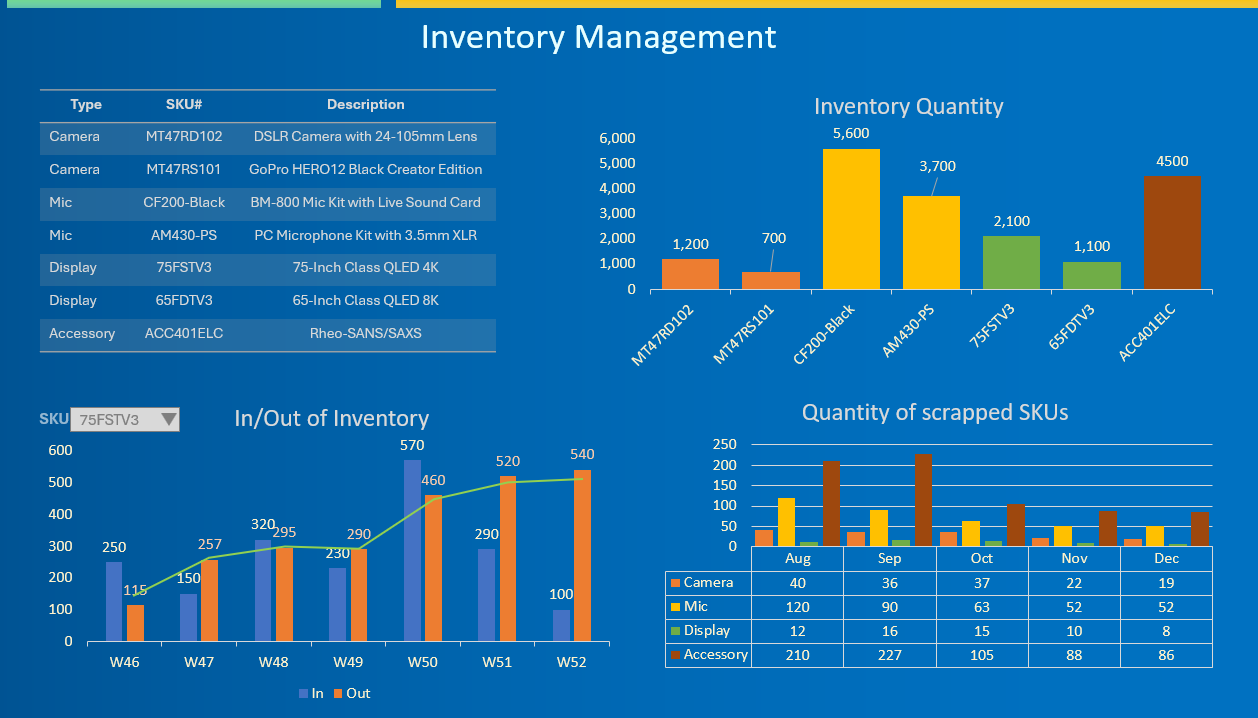

Inventory Management

With AQS’s inventory management system our customers gain access to see their inventory status to make strategic decisions.

We offer comprehensive reporting and data analytics services designed to facilitate the forecasting of sales, revenue, and industry trends. Additionally, our capabilities extend to providing detailed insights into Return Merchandise Authorization (RMA) reasons, monitoring scrap quantities, and analyzing inventory holds to optimize operational strategies.

With AQS’s inventory management system provides valuable real-time visibility into inventory status for customers, enabling them to make informed strategic decisions. The live updates on inventory movements, including shipments going out, incoming inventory, and returns, ensure that customers have accurate and up-to-date information to manage their inventory effectively. This level of transparency and control can greatly enhance operational efficiency and help businesses optimize their supply chain processes..

Warehouse

Our RMA fulfillment center spans over 80,000 square feet. We extend the option for customers to leverage our storage facilities for any surplus materials, with the added convenience of on-demand pallet retrieval. Our expansive warehouse enables us to efficiently manage inventory and execute seamless pick and pack operations, ensuring prompt order fulfillment for shipments.

Other capabilities

Manufacturing / Assembly

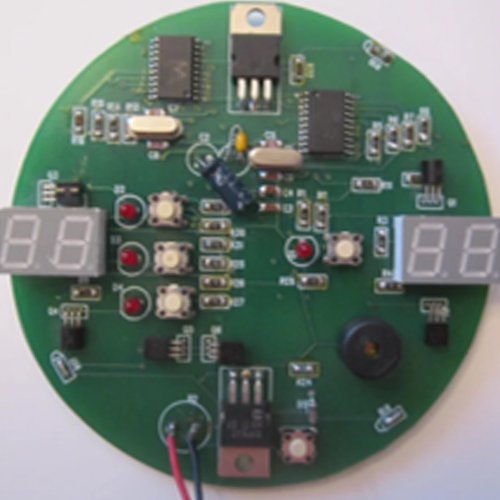

As a global leader in the CMS / EMS (Contract Manufacturing Services / Electronics Manufacturing Services) industry, we offer end-to-end solutions covering engineering development, printed circuit board design, fabrication, parts procurement, assembly, box build, and testing.

Our manufacturing services include rapid prototyping, high-mix low-volume production, New Product Introduction (NPI), high-volume manufacturing, and full turnkey solutions. We also provide cost-effective offshore options and leverage a global supply chain with expertise in managing import tariffs.

For more information on Manufacturing, Mechanical Assembly, Printed Circuit Board Assembly (PCBA)

Visit our website: www.aqs-inc.com

DESIGN

QUOTATION

MAterial sourcing

first article (fa) build

mass production

fulfillment